Navigating EMC Compliance for Electronic Devices

2024년 12월 10일Sarah Chen, Senior Creative Technologist8 min read

Electromagnetic Compatibility (EMC) compliance is a critical hurdle that every electronic device must clear before reaching the market. Whether you're shipping to the US, Europe, or Asia, understanding EMC requirements early in your design process can save months of delays and tens of thousands of dollars in redesign costs. Let's demystify EMC and share practical strategies from our experience certifying hundreds of products globally.

Understanding EMC: The Two-Way Street

EMC ensures electronic devices can coexist peacefully in our increasingly connected world. It's about two fundamental principles:

Electromagnetic Interference (EMI) - Emissions

Your device must not emit electromagnetic energy that interferes with other equipment. Think of it as being a good neighbor - your device shouldn't be "loud" electromagnetically.

- Radiated emissions: EM energy that escapes through the air (30 MHz - 40 GHz)

- Conducted emissions: EM energy that travels along power or data cables (150 kHz - 30 MHz)

- Harmonic currents: Distortion on AC power lines

- Voltage fluctuations/flicker: Power quality impacts

Electromagnetic Susceptibility (EMS) - Immunity

Your device must continue operating correctly when exposed to electromagnetic disturbances from other equipment.

- Radiated immunity: Resistance to RF fields (80 MHz - 6 GHz)

- Conducted immunity: Resistance to RF on cables (150 kHz - 80 MHz)

- ESD immunity: Surviving electrostatic discharge (±4kV contact, ±8kV air)

- EFT/Burst: Fast transients on power/signal lines

- Surge immunity: Lightning and switching transients

- Magnetic field immunity: Power frequency magnetic fields

Global EMC Standards Landscape

Different regions have different EMC requirements, but they're converging over time:

United States (FCC)

- Part 15: Unintentional radiators (most digital devices)

- Part 18: ISM equipment

- Part 68: Telecommunications equipment

- Class A vs B: Commercial/industrial vs residential limits

- Testing: Accredited lab required for certification

European Union (CE Marking)

- EMC Directive 2014/30/EU: Harmonized standards approach

- EN 55032: Multimedia equipment emissions

- EN 55035: Multimedia equipment immunity

- EN 61000-3-x: Power quality standards

- EN 61000-4-x: Immunity test methods

- Self-declaration: Allowed with proper technical documentation

International (CISPR/IEC)

- CISPR 32: Multimedia equipment (replacing CISPR 13/22)

- CISPR 35: Multimedia immunity

- IEC 61000 series: Generic EMC standards

- Product-specific: Medical (IEC 60601-1-2), Automotive (CISPR 25)

Design for EMC Success: Prevention is Cheaper than Cure

Good EMC performance starts at the schematic level. Here are battle-tested techniques from our design reviews:

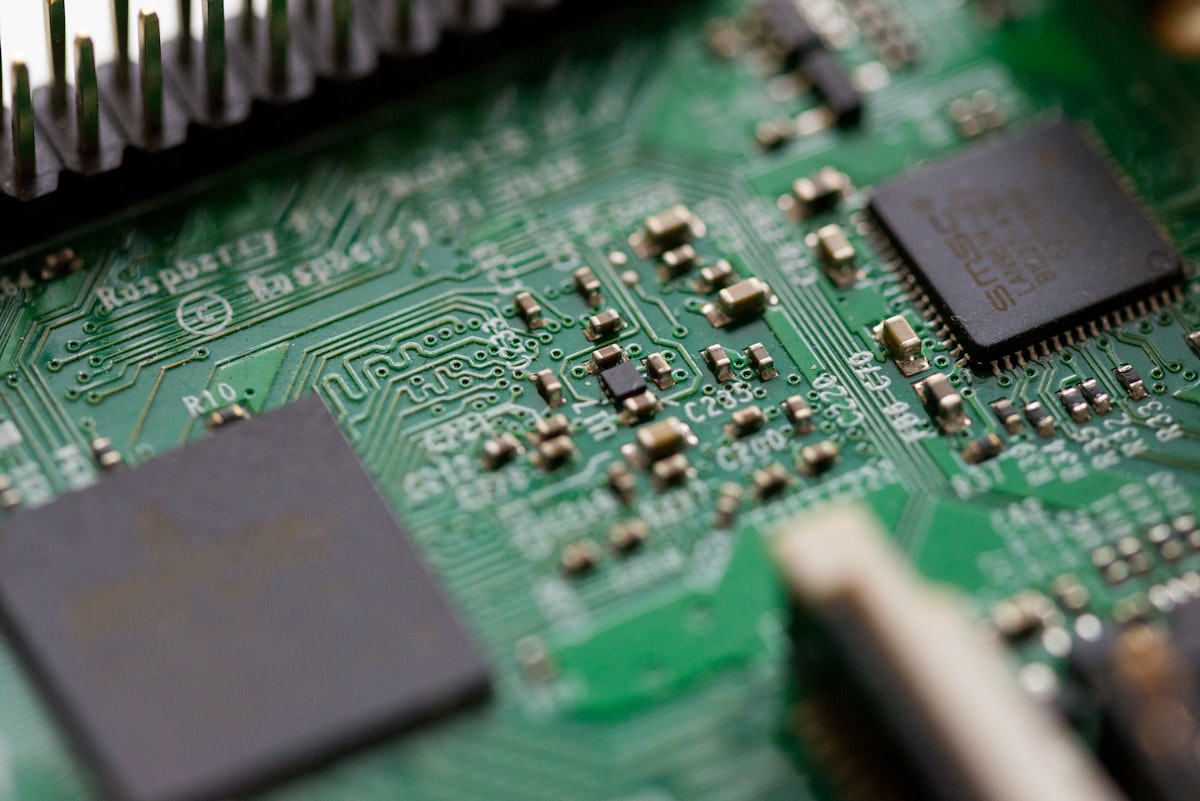

PCB Layout: Your First Line of Defense

- Stack-up strategy:

- 4-layer minimum for digital designs >25 MHz

- Adjacent power/ground planes for image planes

- Signal-Ground-Power-Signal for optimal shielding

- Critical routing rules:

- Keep high-speed traces >3x width from board edge

- No traces crossing split planes (creates antennas)

- Differential pairs: matched length, constant spacing

- Clock traces: shortest path, away from I/O

- Return path management:

- Continuous ground plane under all high-speed signals

- Minimize via transitions (each via is a discontinuity)

- Stitch vias along plane transitions (λ/20 spacing)

Power Supply Design

Power supplies are often the biggest EMC culprits. Key strategies:

- Input filtering:

- Common-mode choke + X/Y capacitors

- Multi-stage filtering for switch-mode supplies

- Keep filter close to power entry

- Switching frequency:

- Dither/spread spectrum to reduce peaks

- Avoid amateur radio bands if possible

- Consider synchronization in multi-converter systems

- Layout considerations:

- Minimize hot loops (switch node area)

- Shield inductors or use toroidal cores

- Snubbers on switching nodes (test values empirically)

Decoupling Strategy

Proper decoupling prevents your ICs from becoming unintentional transmitters:

- Capacitor selection:

- 0.1µF ceramic per power pin (general purpose)

- 1-10nF for >100 MHz frequencies

- Bulk capacitors per power rail (10-100µF)

- Low ESR/ESL types (X7R, X5R dielectric)

- Placement rules:

- Within 5mm of IC power pins

- Direct via to ground plane (no traces)

- Multiple vias for lower inductance

I/O Protection and Filtering

Every cable is an antenna. Protect and filter all external interfaces:

- Common-mode filtering: Ferrite beads on differential pairs

- ESD protection: TVS diodes on all external pins

- Series resistance: 22-100Ω on digital I/O to slow edges

- Shield termination: 360° connection to chassis ground

Shielding: When Prevention Isn't Enough

Sometimes you need physical barriers to contain emissions or block interference:

Enclosure Design

- Material selection:

- Aluminum: Good shielding, lightweight, moderate cost

- Steel: Excellent low-frequency shielding, magnetic

- Conductive plastic: Lightweight but limited effectiveness

- PCB shields: Targeted shielding for specific circuits

- Aperture management:

- Maximum dimension < λ/20 at highest frequency

- Use honeycomb vents for cooling (maintains shielding)

- Gaskets on all seams (conductive elastomer or finger stock)

Cable Shielding

- Shield types: Foil (high frequency), braid (low frequency), combination

- Termination: Both ends for electric fields, one end for magnetic

- Connectors: Metal shells with 360° shield connection

- Pigtails: Avoid at all costs (destroys shield effectiveness)

Pre-Compliance Testing: Find Problems Early

Full EMC testing costs $10,000-$30,000 per iteration. Pre-compliance testing in your lab can save significant time and money:

DIY EMC Test Setup

- Near-field probes: $500-$2000 kit for emission hot-spot finding

- Spectrum analyzer: USB-based units from $2000

- LISN: Line Impedance Stabilization Network for conducted emissions

- TEM cell: Small shielded chamber for radiated testing

- Current probes: Measure common-mode currents on cables

Pre-Compliance Process

- Baseline measurement: Identify emission peaks and margins

- Diagnostic mode: Disable subsystems to isolate sources

- Iterative fixes: Apply solutions and re-measure

- Margin verification: Ensure 6dB margin for production variation

- Documentation: Record all changes for compliance report

Common EMC Failures and Solutions

Learn from these frequent issues we see in testing:

Radiated Emissions Failures

- Clock harmonics:

- Problem: Crystal oscillator harmonics exceeding limits

- Solution: Add series resistor, improve ground plane, shield oscillator

- Cable radiation:

- Problem: I/O cables acting as antennas

- Solution: Common-mode chokes, improved filtering, cable shields

- Power supply noise:

- Problem: Switching noise radiating from PCB

- Solution: Snubbers, shielding, spread spectrum, layout optimization

Conducted Emissions Failures

- Differential mode: Add X-capacitors, increase inductance

- Common mode: Y-capacitors, common-mode choke, improve grounding

- Resonances: Damping resistors, adjust filter values

ESD Failures

- Direct discharge: Add TVS diodes, improve ground paths

- Indirect discharge: Shield sensitive circuits, firmware recovery

- Air discharge: Increase creepage distances, add barriers

EMC Testing Process: What to Expect

Understanding the testing process helps you prepare effectively:

Test Planning

- Standards selection: Based on product type and target markets

- Test plan creation: Define configurations, modes, cables

- Sample preparation: Production-representative units

- Documentation: Schematics, layouts, BOM, manual

During Testing

- Configuration: Test worst-case scenarios (max clock, all I/O active)

- Monitoring: Watch for intermittent failures

- Debugging: Have tools and components ready for fixes

- Documentation: Photograph setup, record all modifications

Post-Testing

- Test report: Review for accuracy and completeness

- Design updates: Implement all modifications in production

- Re-testing: Required for significant changes

- Filing: FCC ID, DoC preparation, CE technical file

Cost-Effective EMC Strategies

Balancing EMC performance with product cost:

Design Trade-offs

- Layer count: 4-layer often sufficient with good layout

- Shielding: Selective shielding vs. full metal enclosure

- Components: Standard filters vs. custom designs

- Margins: Design for 6dB margin, not 20dB over-engineering

Testing Optimization

- Pre-scanning: Quick check before full compliance

- Modular certification: For RF modules

- Family testing: Leverage similar product data

- Self-declaration: Where allowed (CE for low-risk products)

EMC Checklist for Your Next Design

Use this checklist to avoid common EMC pitfalls:

Schematic Review

- □ Power input filtering designed

- □ Decoupling capacitors specified for all ICs

- □ I/O protection on external interfaces

- □ Crystal circuits include load capacitors and series resistor

- □ Reset circuits have proper filtering

Layout Review

- □ Continuous ground plane(s)

- □ No traces crossing plane splits

- □ High-speed signals routed away from board edges

- □ Proper via stitching around board perimeter

- □ Decoupling capacitors placed correctly

Mechanical Review

- □ Shield/enclosure design complete

- □ Cable entry points addressed

- □ Apertures minimized and filtered

- □ Gasket specifications defined

- □ Grounding scheme documented

Partner with EMC Experts

EMC compliance doesn't have to be a roadblock. With proper planning and design practices, most products can pass on the first or second attempt. Our engineering team has guided hundreds of products through EMC certification across all major markets. We offer:

- Design reviews focused on EMC risks

- Pre-compliance testing in our Shenzhen facility

- Debugging support during formal testing

- Cost-optimized solutions that meet requirements

- Global certification project management

Don't let EMC compliance delays impact your product launch. Our experienced team can identify and resolve potential issues before they become expensive problems.

Contact our EMC specialists at rfq@source.parts for testing support and compliance consultation. We'll help ensure your product meets global requirements efficiently.

관련 기사

PCBElectronics Design

Understanding PCB Design: A Comprehensive Guide

Dive deep into the fundamentals of Printed Circuit Board (PCB) design, from schematics to layout.

더 읽기